10 bestVibration Isolation Padsof September 2025

112M consumers helped this year.

1

Anpro 2 Pieces Studio Monitor Acoustic Isolation Pads, Stabilizer Speaker base, 12“x 7”x 1.5“/ 30cm x 17cm x 3.5cm(Black)

Anpro

9.7

2

BXI - Anti Vibration Isolation Pads - Rubber & Cork Pad - Thick & Heavy - Excellent at Low Frequencies, Great Acoustic Isolation for Speakers, Washers, Machines, etc (6'' X 6'' X 2'', 2 Pack)

BXI

9.4

25% off

3

phepetroll 4P Anti Vibration Pads 4'' X 4'' X 7/8" Sound Isolation Ribbed Rubber Mats With EVA Center, Heavy Duty Vibration Isolation Pads for Air Compressos, Conditioner, Treadmill, HVAC Washer Dryer

phepetroll

9.1

4

Air Jade Rubber Anti-Vibration Pads, 3" x 3" x 7/8" Heavy Duty EVA Vibration Isolation Pads Mats for HVAC, Washers, Compressors, Treadmills, Air Conditioner, 4 Pack

Air Jade

8.8

5

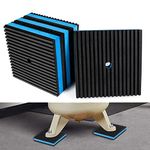

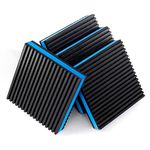

Forestchill Heavy Duty Rubber Anti-Vibration Pads, 4" X 4" X 7/8" Ribbed Rubber with Blue EVA Center Isolation Pad for HVAC, Air Compressor, Washer and Dryer, Air Conditioner Units (Pack of 4)

Forestchill

8.5

Other

6

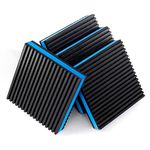

Forestchill Heavy Duty Rubber Anti-Vibration Pads, 3" X 3" X 7/8" Ribbed Rubber with Blue EVA Center Isolation Pad for HVAC, Air Compressor, Washer and Dryer, Air Conditioner Units (Pack of 4)

Forestchill

8.3

7

Wintcomfort Anti Vibration Pad with Ribbed Rubber, 3" x 3" x 7/8" Blue EVA Center Isolation Pads Mats for Heavy Duty Equipment, HVAC, Compressors, Air Conditioner Units, Washer and Dryer, 4 Pack

Wintcomfort

8.0

8

Forestchill Rubber Anti Vibration Pads, 4" × 4" × 7/8" Heavy Duty Ribbed Rubber Anti-Vibration Isolation Pads with EVA Center Layer for Air Compressor, Air Conditioner Unit, HVAC, Treadmill

Forestchill

7.7

9

LBG Products Anti-Vibration Rubber Isolation Pads with Cork Material,4" X 4" X 7/8" Heavy Duty Blue EVA Isolation Pad for Air Conditioner,Compressors,HVAC,Treadmills etc

LBG Products

7.4

10

Flehomo Anti-Vibration Pads, 3" x 3" x 7/8" Rubber Pad with EVA Foam Center, Heavy Duty Isolation Pads for Condenser Units, Air Compressor, HVAC, Washer and Dryer, Pack of 4

Flehomo

7.1

A Guide to Selecting the Best Vibration Isolation Pads

Vibration-isolation pads are used to reduce or eliminate the transfer of vibrations from machines or appliances to the floor or surrounding structures. This is important for protecting equipment, reducing noise, and preventing damage to floors or nearby objects. When choosing the right vibration-isolation pad, it's important to consider the type of equipment you have, the environment where it will be used, and the specific needs for vibration reduction. Understanding the key specifications will help you select a pad that offers the best performance for your situation.

Load Capacity

Load capacity refers to the maximum weight that a vibration-isolation pad can support without losing its effectiveness. This is crucial because using a pad with too low a load capacity can cause it to compress too much, reducing its ability to isolate vibrations. Load capacities are usually divided into light-duty (for small appliances or electronics), medium-duty (for items like washing machines or HVAC units), and heavy-duty (for industrial machinery). To pick the right one, estimate the weight of your equipment and choose a pad that can comfortably support it, ideally with some margin for safety.

Material Type

The material of the pad affects its durability, resistance to chemicals, and how well it absorbs vibrations. Common materials include rubber, neoprene, cork, and composite blends. Rubber is flexible and good for general use, neoprene offers better resistance to oils and chemicals, cork is eco-friendly and suitable for lighter loads, and composites combine properties for specialized needs. Your choice should depend on the environment (such as exposure to oils or outdoor use) and the type of vibration you need to control.

Pad Thickness

Pad thickness determines how much the pad can compress and absorb vibrations. Thicker pads generally provide better isolation but may be less stable for very heavy equipment. Thin pads are suitable for lighter loads or where space is limited. If your equipment generates strong vibrations or is placed on a hard surface, a thicker pad may be more effective. For smaller, lighter items, a thinner pad is usually sufficient.

Durometer (Hardness)

Durometer measures the hardness of the pad material, usually on a scale from soft to hard. Softer pads absorb more vibration but may compress too much under heavy loads, while harder pads support heavier equipment but may transmit more vibration. For light, sensitive equipment, a softer pad is ideal. For heavy machinery, a harder pad is better to maintain stability while still providing some isolation.

Size and Shape

The size and shape of the pad should match the footprint of your equipment. Larger pads distribute weight more evenly and can provide better stability, while smaller pads are easier to fit in tight spaces. Some pads are square, rectangular, or circular, and the right shape depends on the base of your equipment. Measure the contact points of your equipment and choose pads that fit well to ensure effective vibration isolation.

Temperature Resistance

Temperature resistance indicates how well the pad can perform in extreme hot or cold conditions. Some materials may harden or soften with temperature changes, affecting their performance. If your equipment operates in a place with significant temperature fluctuations, such as outdoors or near heat sources, look for pads rated for a wide temperature range to ensure consistent vibration isolation.

Best Reviews Guide Newsletter

Get exclusive articles, recommendations, shopping tips, and sales alerts

Sign up for our newsletter to receive weekly recommendations about seasonal and trendy products

Thank you for subscribing!

By submitting your email address you agree to our Terms and Conditions and Privacy Policy